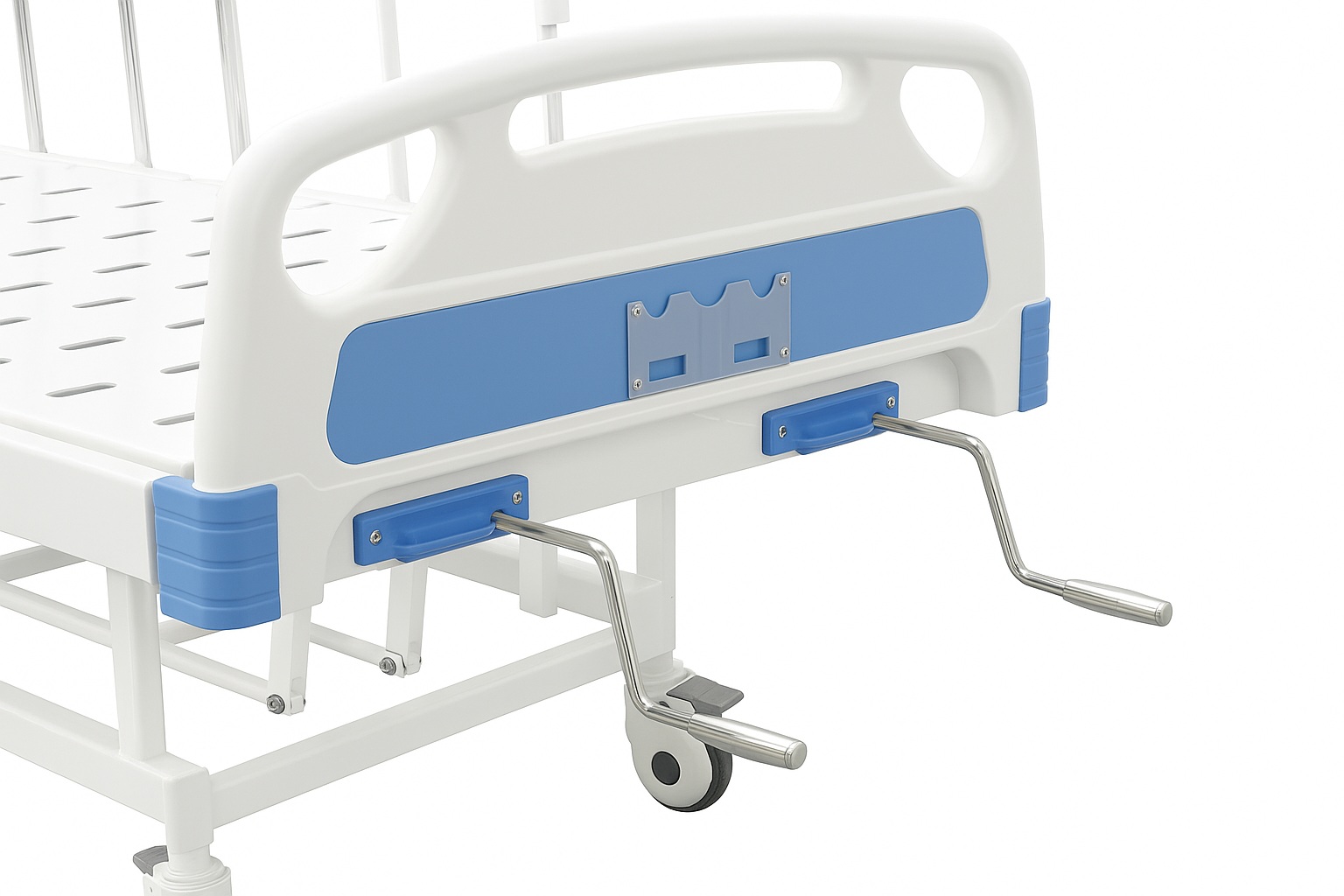

Hospital bed crank handle is right at the heart of uptime for manual beds. When a handle breaks, height and backrest adjust don’t happen, workflows stall, and staff gets frustrated. Good news: a solid, affordable replacement crank is simple to source, quick to instal, and it pays off in less downtime.

Quick links on our site:

• Hospital Bed Crank Handle (Category)

• Hospital Bed Crank Handle (Product Page)

• HOSPITAL BED SOLUTIONS

Manual beds still run in many wards, long-term care, and home care setups. A reliable crank handle keeps adjustments smooth, protects your schedule, and reduces back-and-forth calls to maintenance. It’s small hardware with outsized impact. And it’s budget-friendly—no need to retool a whole frame or drivetrain just to fix a hand grip.

Core benefits you can feel on day one

Getting fit right is everything. Think interface shape + shaft length + handle diameter. If those align, you’re basically done.

| Spec & Step | What to Confirm | Why it Matters | Risk if Wrong |

|---|---|---|---|

| Interface type | Positive-fit hex or square; check engagement depth | Ensures proper torque transfer and no wobble | Handle slips, rounding, or binds |

| Shaft/insert length | Match old part; check stop shoulder | Full engagement without bottoming out | Partial bite; premature wear |

| Handle diameter | Medium-thick, glove-friendly | Comfort, lower effort per turn | Hand fatigue, slower turns |

| Material | ABS shell + stainless or aluminum core | Cleanability + durability | Rust, cracks, rough edges |

| Foldable/removable | Fold or pull-off after use | Prevent bumps and snags | Safety incidents; damaged linens |

| Fastener style | Set screw / detent pin / push-fit | Correct retention method | Walk-off, lost handle |

| Finish | Smooth, no burrs; rounded corners | Better feel; fewer complaints | Scrapes; QC returns |

| Marking | Direction arrows or icons | Less training time | Mis-turn, rework |

Browse parts here: Hospital Bed Crank Handle (Category) and confirm specs before PO.

| Option | Interface | Core Material | Remove-after-use | Typical Use Scene | Notes |

|---|---|---|---|---|---|

| Universal hex | Hex | Stainless | Yes | General wards, LTC | Great torque transfer |

| Universal square | Square | Aluminum | Yes | Home care, community | Lighter feel, smooth spin |

| Fold-down knob | Hex/Square | Stainless | Folds | Tight spaces near rails | Saves knuckle clearance |

| Long-arm handle | Hex/Square | Stainless | Yes | Heavy users, frequent crank | More leverage, slower RPM |

| Short-arm handle | Hex/Square | Aluminum | Yes | Quick tweaks, light duty | Faster RPM, less leverage |

Ready to source? See the Hospital Bed Crank Handle (Product Page) or talk to our team at HOSPITAL BED SOLUTIONS.

A mid-sized district hospital ran into problems when their electric beds lost power during rolling blackouts. Staff kept a set of manual beds as backup. The only snag? Several handles had gone missing. By stocking affordable hospital bed crank handle replacements in bulk, the hospital cut downtime. Nurses swapped handles in seconds, adjusted height, and kept patient flow moving without waiting on electricians. Lesson: cheap parts can save hours of disruption.

In a long-term care center, caregivers crank beds dozens of times per day—raising backs, lowering legs, shifting height. Their older square-drive handles wore down fast. Switching to stainless-core hex handles gave smoother torque and reduced wrist strain. Staff reported less fatigue, and facility managers liked the lower replacement frequency. Small upgrade, big impact on daily workflow.

Q: Will a universal hospital bed crank handle fit my mixed fleet of manual beds?

A: If the interface shape and depth match, likely yes. Bring one old piece when you order and check the bite. Simple and fast.

Q: Hex or square—what should we pick?

A: Go with what your frames use now. Hex often gives a tight, positive feel; square is rugged and simple. Consistency wins for spare parts.

Q: Fold-down or fixed?

A: Tight rooms love fold-down. If you want max leverage, a longer fixed arm is fine—just remember the remove-after-use routine.

Q: Can we brand it or change colors?

A: Sure—OEM/ODM is available so you keep a clean fleet look and clear department IDs.

A hospital bed crank handle isn’t glamorous, but it’s mission-critical for manual beds. Choose the right interface, pick a comfortable grip, and keep a few spares on the shelf. That’s how you cut downtime, reduce noise in the workflow, and keep staff moving. When you need consistent supply and custom specs, tap HOSPITAL BED SOLUTIONS—we support OEM/ODM, bulk orders, and tailored packaging so you can roll out fast.

Explore now: