Hospital bed crank handles choice decides how easy the bed feels in daily use. When the handle runs smooth, staff finish tasks faster, and the bed stays in-service longer.. For nurses, caregivers, and facility staff, the crank isn’t just a tool—it’s a lifeline when you need to adjust bed height or angle quickly. Durable crank handles can mean the difference between smooth workflows and constant frustration.

At Medequip Supplier, the focus is not only on building strong hospital beds, but also on ensuring every moving part—like the crank handle—works reliably in daily use. Buyers from hospitals, nursing facilities, or wholesale distributors know well that a weak link in furniture design adds cost and downtime.

Want a quick look at options? See our in-house pages:

Goal: lower effort, better grip, fewer awkward wrist angles.

Ergo quick-check table

| Design factor | What to check | Why it matters | Field note |

|---|---|---|---|

| Knob diameter | Comfortable grasp, non-slip surface | Less hand strain | “Glove on” test it |

| Arm length | Enough leverage without hitting rails | Lower turning force | Try full sweep |

| Bearing/bushing | No squeak, no binding | Smooth feel, fewer complaints | Drop-test then spin |

| Backlash | Minimal play at the tip | Accurate angle changes | Check start/stop gaps |

Foldable vs fixed comparison

| Handle type | Best scenario | Pros | Watch-outs |

|---|---|---|---|

| Foldable/hidden | Tight rooms, high traffic | Safer pass-through, cleaner profile | Hinge quality must be solid |

| Fixed solid bar | Low-traffic rooms, budget builds | Fewer moving parts | May protrude, trip risk |

Electric beds dominate many hospitals today, but every facility manager knows one thing—power failures happen. During blackouts or system breakdowns, an electric-only bed can freeze.

Here’s where the manual hospital bed crank handle plays a critical role:

Think of it as an insurance policy built into the bed. Hospitals that overlook this detail often regret it the first time the lights go out.

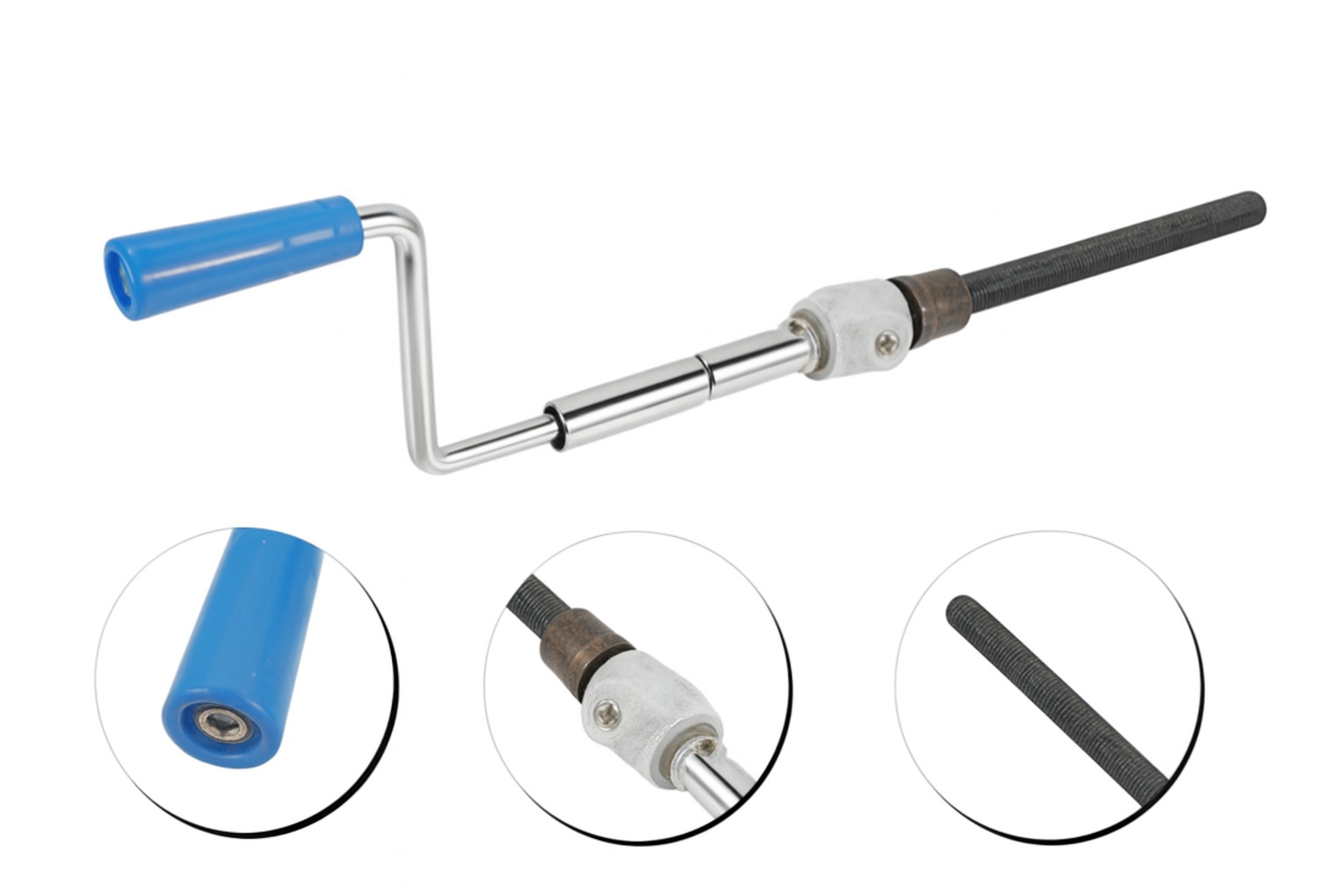

What lasts longer? Stainless steel arms + ABS or nylon knobs are the classic combo. Zinc-plated steel also works when you want extra stiffness.

Materials & finish table

| Component | Common spec | Strength | Cleanability | Notes |

|---|---|---|---|---|

| Arm | SS or zinc-plated steel | High | High | Pick rounded edges |

| Knob | ABS / PA (nylon) | Medium | High | Add soft-touch sleeve |

| Socket | Hardened steel | Very high | Medium | Keep grease minimal |

| Hinge (foldable) | SS pin + alloy body | High | High | No wobble after cycles |

These are not abstract features—they’re daily realities in healthcare settings.

Need an OEM/ODM match? Talk to HOSPITAL BED SOLUTIONS. We support drawings, samples, and bulk runs aligned with your bed frames and drive trains.

| Spec topic | Typical range | What to ask supplier | Why you ask |

|---|---|---|---|

| Handle arm length | mid-length (balanced leverage) | Any interference with side rails? | Smooth full sweep |

| Knob diameter | mid-size, grippy | Glove-on grip test passed? | Real-world control |

| Surface finish | SS brushed / zinc-plated + coat | Cleaner compatibility list? | Faster wipe-downs |

| Fold hinge life | repeated open/close | Any wobble after cycles? | Long-term feel |

| Backlash | minimal at tip | How do you control play? | Precise angle set |

We build for distributors, importers, hospitals, long-term care, and home-care buyers who need reliability and bulk readiness. If you want custom knob styles, arm lengths, or branding, we’ll co-engineer and run PPAP-like samples—fast. It’s not rocket sciense, but details matter.

For hospital administrators and medical equipment distributors, durable crank handles bring commercial advantages:

At Medequip Supplier, our HOSPITAL BED SOLUTIONS aren’t just about beds. They’re about every detail that keeps beds usable, safe, and long-lasting. When wholesalers buy in bulk or OEM/ODM customers request custom specifications, we ensure crank handles match the same durability standards as the bed frames.

A hospital bed crank handle may look like a minor part, but in real-world hospital or nursing care environments, it’s one of the most touched and tested components. From ergonomic comfort to emergency reliability, foldable safety to compliance assurance, the crank handle plays a bigger role than most buyers imagine.

Whether you’re a hospital procurement manager, a nursing facility buyer, or a medical equipment distributor, don’t overlook this detail. Durable crank handles mean less downtime, safer wards, and a better overall investment in your hospital bed furniture.

For bulk orders, customization, or OEM/ODM hospital bed solutions, Medequip Supplier is here to support your projects worldwide.