If you’re choosing Hospital bed mattresses for a busy ward or long-term facility, waterproof covers aren’t a “nice to have.” Hospital bed mattresses are not just about comfort. In active wards or long-term treatment centers, they lug a big tons of threat and responsibility. Include waterproof covers to the mix, and you unexpectedly have a barrier that protects people, team, and of course, your bottom line.

Seems simple, yet in technique it’s messy. Liquids leakage, covers rip, cleansing team rush through turn-arounds, and instantly that shiny “brand-new” cushion smells bad or worse– harbors concealed germs.

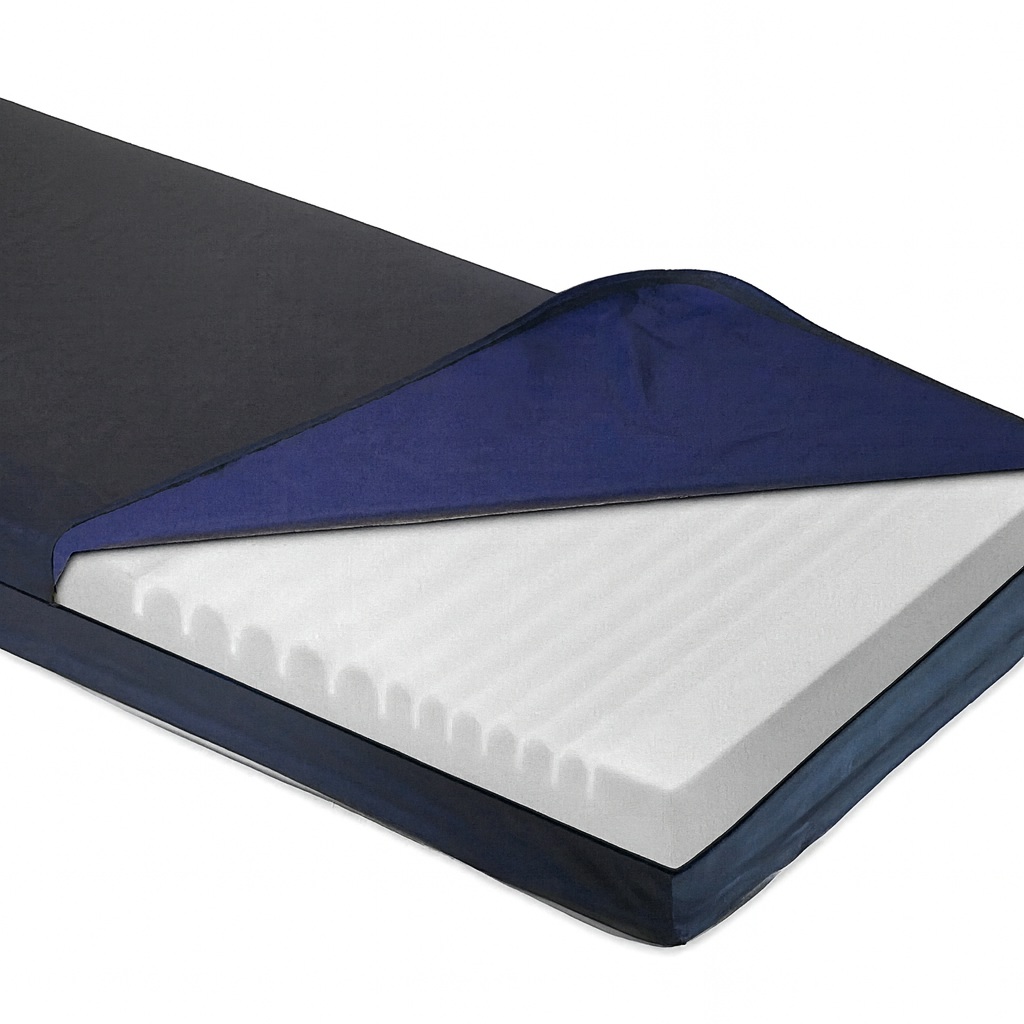

This is where waterproof covers become non-negotiable. They stop fluids from seeping inside, protect the foam core, and make daily cleaning actually effective. Without them, even the most expensive hospital bed mattress will fail too fast.

Hospital environments are high-risk. Once a mattress core gets wet, it’s almost impossible to disinfect. Studies reported more than 700 cases of fluid ingress linked to damaged mattress covers in just a few years. That’s not just about money—it’s about contamination risk spreading from one patient to the next.

For purchasing teams: add “100% waterproof sealed cover” as a line item in your RFQ.

In real-world audits, between 20% and 47% of hospital bed mattresses showed damage or wear. Tears, punctures, and worn zippers all create gaps where fluids and bacteria hide.

So the question isn’t if waterproof covers fail, but when. That’s why inspection routines matter. Procurement shouldn’t just ask, “Is it waterproof?” Instead, ask, “How long can this cover survive daily cleaning, disinfection, and rough handling?”

| Argument | Evidence / Findings | What it means for you |

|---|---|---|

| Stop cross-contamination | 700+ FDA reports of fluid leaks from damaged covers | Invest in real waterproof design, not just “water-resistant” marketing |

| Damage is common | 20–47% of mattresses show wear in audits | Regular inspection and replacement cycles save more than skipping |

| Cleaning matters | CDC & NHS stress following manufacturer cleaning instructions | Staff training and SOPs are as important as the product |

| Design details | Welded seams & zipper covers outperform stitched seams | Write specs carefully in tenders to avoid cheap substitutes |

| Pressure risk | Waterproof covers don’t equal pressure prevention | Match mattress type to patient risk level (foam, air, hybrid) |

Want a reference layout for specs? Check our Hospital Bed Mattress category and map its cover features to your facility SOP. Easy win.

Even with strict cleaning protocols, a damaged surface can’t be fully disinfected. That’s why both CDC and NHS guidelines stress using waterproof covers that survive repeated disinfection. Not all fabrics are equal. Some lose integrity after a few washes, others shrink or crack.

Look for covers tested under ISO standards for cleaning durability. That’s a mouthful, but it basically means: they won’t fall apart after routine wipe-downs with hospital-grade disinfectants.

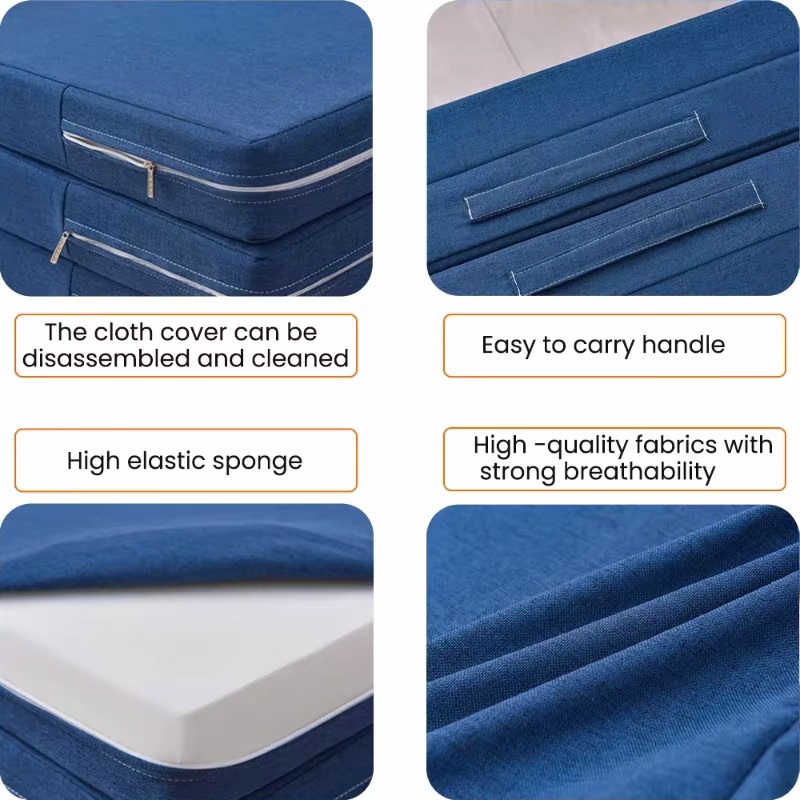

Let’s be honest: some covers look “waterproof” until you see the stitching. Needle holes, weak zippers, or glued seams all open doors for leaks. A better design uses welded seams and “waterfall” flaps over zippers. It’s small details like this that separate a reliable hospital bed solution from a cheap one that causes headaches later.

Here’s the tricky balance: yes, you want a waterproof cover. But if it traps heat and moisture, skin problems and complaints follow. That’s why modern covers also list moisture vapor transmission rate (MVTR), meaning they allow airflow while still blocking liquids.

It’s not about comfort only—it keeps the mattress usable for longer, reduces odors, and makes patient care easier.

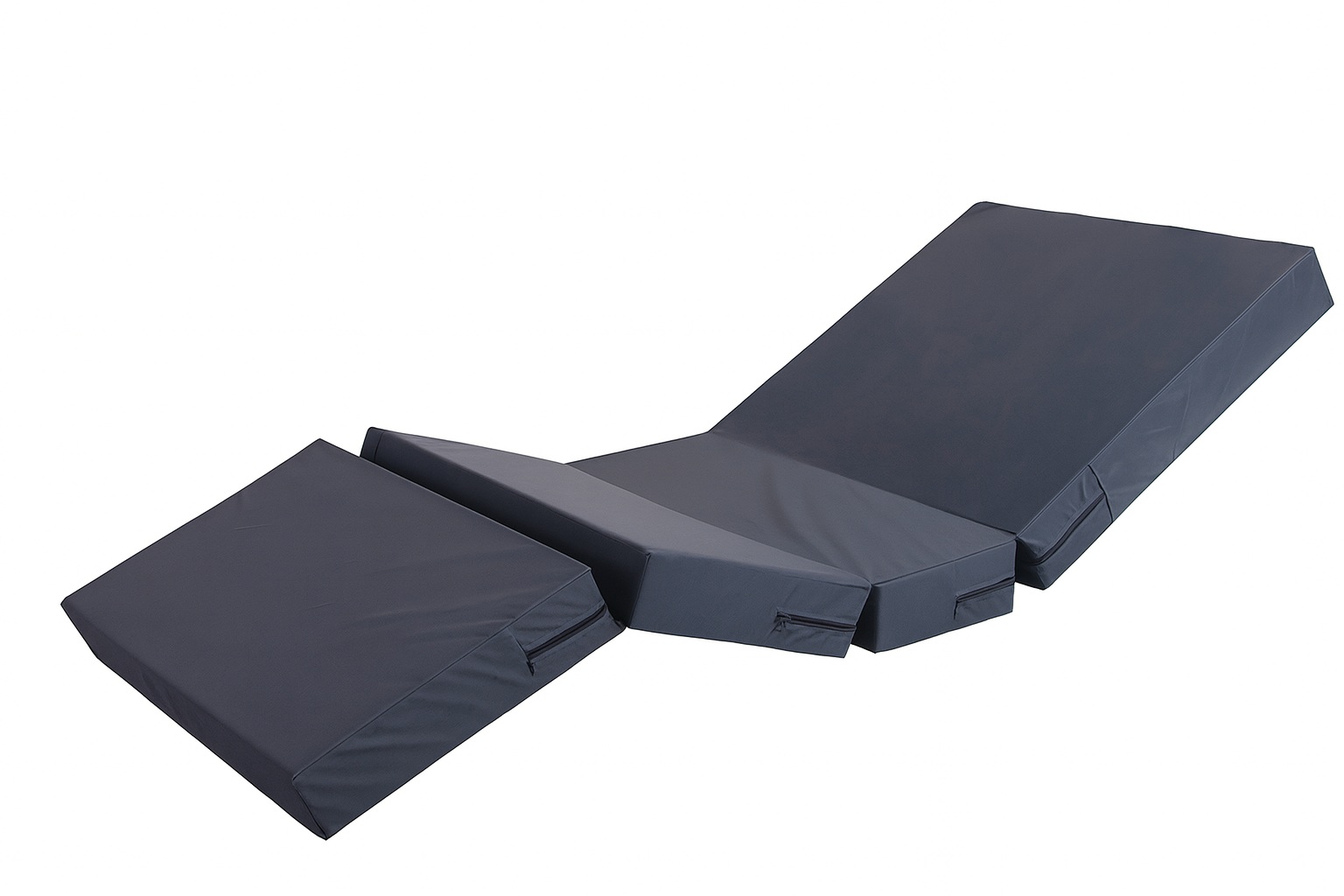

Some people think waterproof automatically means “high-tech clinical mattress.” That’s wrong. A waterproof cover only keeps the inside safe. To prevent pressure-related issues, you still need to choose the right support surface—like alternating air mattresses or hybrid designs.

So the cover is the baseline, not the full solution.

If you’re consolidating sourcing, anchor your kit under HOSPITAL BED SOLUTIONS and keep cover specs uniform across models. Fewer surprises, smoother SOP.

If you’re writing tender docs or sourcing hospital bed furniture, don’t just write “hospital bed mattress, waterproof.” That’s too vague. Instead:

This is how you avoid getting cheap foam mattresses with paper-thin “water-resistant” fabric that tears after two months.

For distributors and procurement managers, waterproof covers are not just hygiene tools—they’re business assets. Why?

And this is where our Hospital Bed Solutions matter. Offering OEM/ODM hospital bed mattresses means you can get the waterproof cover designed for your exact facility needs, whether that’s heavy ICU use, home care turnover, or bulk supply for distribution.

At the end of the day, waterproof covers are not just fabric. They are part of the Hospital Bed Furniture system. A small detail that solves big headaches: hygiene, compliance, staff time, mattress durability.

For distributors and procurement managers, this means one thing: demand will keep rising. And suppliers who can deliver OEM/ODM hospital bed mattresses with reliable waterproof covers will always be at the front of the line.

So when you think hospital mattresses, think waterproof first. Because no one in a hospital wants to deal with what’s under the cover when it fails.