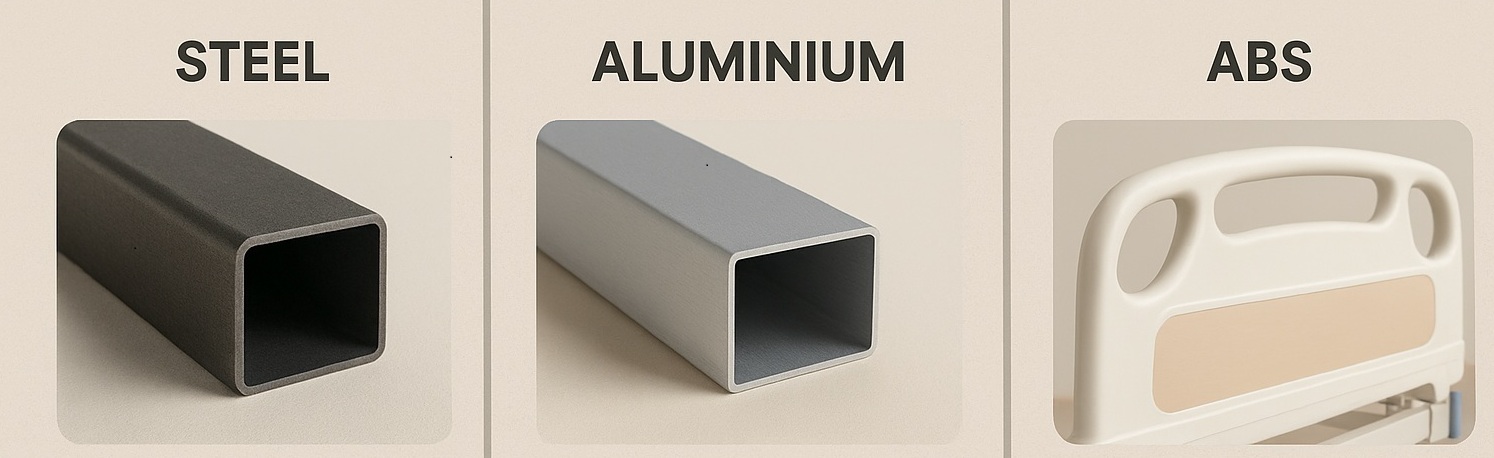

When you’re looking at clinical facility bed home furnishings, sturdiness isn’t just a nice additional– it’s vital. Healthcare facility beds operate 24/7. People move, caretakers transform, accessories slide in and out. That constant pressure means the choice of material can make or break long-term performance. Let’s break down how steel, aluminum, and ABS each play their role in modern Hospital Bed Furniture.

Consider it: a bed structure that bends, side rails that rattle, or a table board that splits can swiftly become a headache for personnel and a threat for clients. Hospitals, nursing centers, and even home care arrangements need devices that lasts. That’s why Health Center Bed Furniture is routinely crafted from 3 significant products– steel, lightweight aluminum, and ABS plastic. Each has its strengths, concessions, and best-fit situations.

Steel is the heavy hitter. You’ll find it in hospital bed side rails, bed castors, and sometimes the main frames themselves.

Aluminum shows up a lot in aluminum side rails, crank handles, and adjustable bed sections.

ABS plastic is everywhere in hospital accessories: bed head & foot panels, overbed table boards, and cabinet fronts.

| Material | Strengths | Weaknesses | Best Fit in Hospital Bed Furniture |

|---|---|---|---|

| Steel | High load capacity, long-lasting, stable | Heavy, needs anti-rust coating | Bed frames, heavy-duty side rails, castors |

| Aluminum | Lightweight, rust-resistant, sleek look | Less stiff than steel, premium alloys cost more | Side rails, crank handles, adjustable bed sections |

| ABS | Impact-resistant, light, easy to clean, customizable | Not for high load, heat/UV sensitive | Headboards, footboards, overbed tables, cabinet fronts |

Hospitals don’t buy furniture for style alone. They buy it to solve problems:

This is where HOSPITAL BED SOLUTIONS come in. The best suppliers don’t push one material—they recommend a mix. For example: a steel frame, aluminum rails, and ABS headboards deliver strength, safety, and usability all in one package.

Choosing the right material isn’t only about performance. It’s also about long-term cost efficiency and meeting procurement standards. Distributors and hospital managers look for:

By using customized hospital bed furnishings— steel where it counts, aluminum where it assists, ABS where it conserves– you meet both resilience and spending plan needs.

Steel, aluminum, and ABS each bring unique value to Hospital Bed Furniture. The smartest hospital bed solutions use them together: steel for core strength, aluminum for adjustability, ABS for usability and design.

For hospital procurement teams, distributors, or care facilities, the right mix means fewer headaches, better patient safety, and smarter business. And that’s exactly where OEM/ODM partners like Hospital Bed Furniture make the difference—delivering durable, flexible, and scalable solutions for a demanding healthcare world.