You’re picking a 3 crank hospital bed because you want the sweet spot: solid functions, low upkeep, and pricing that doesn’t punch a hole in the budget. This piece walks you through which types of suppliers actually support real customization, where OEM/ODM fits, and how to map specs to your use cases. I’ll also point out concrete SKUs from our own catalog so you can click through fast.

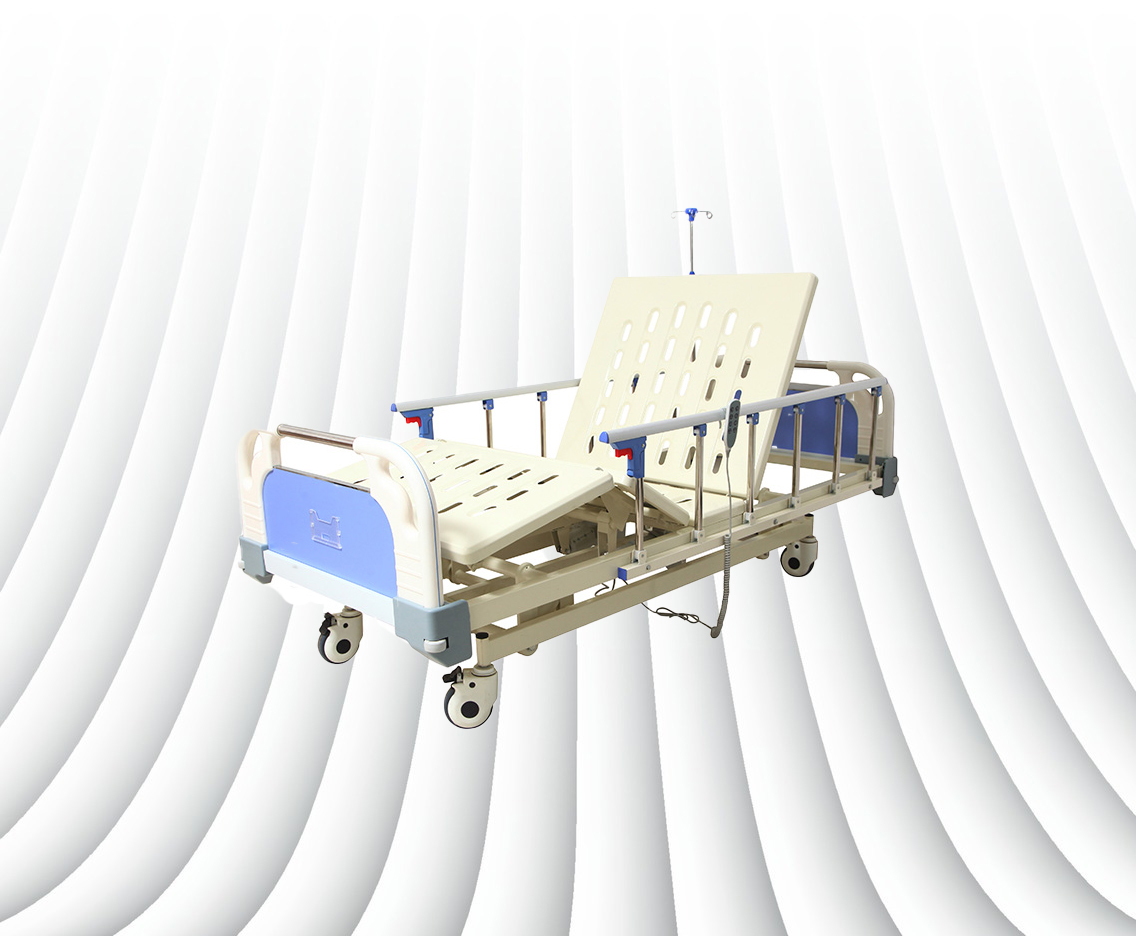

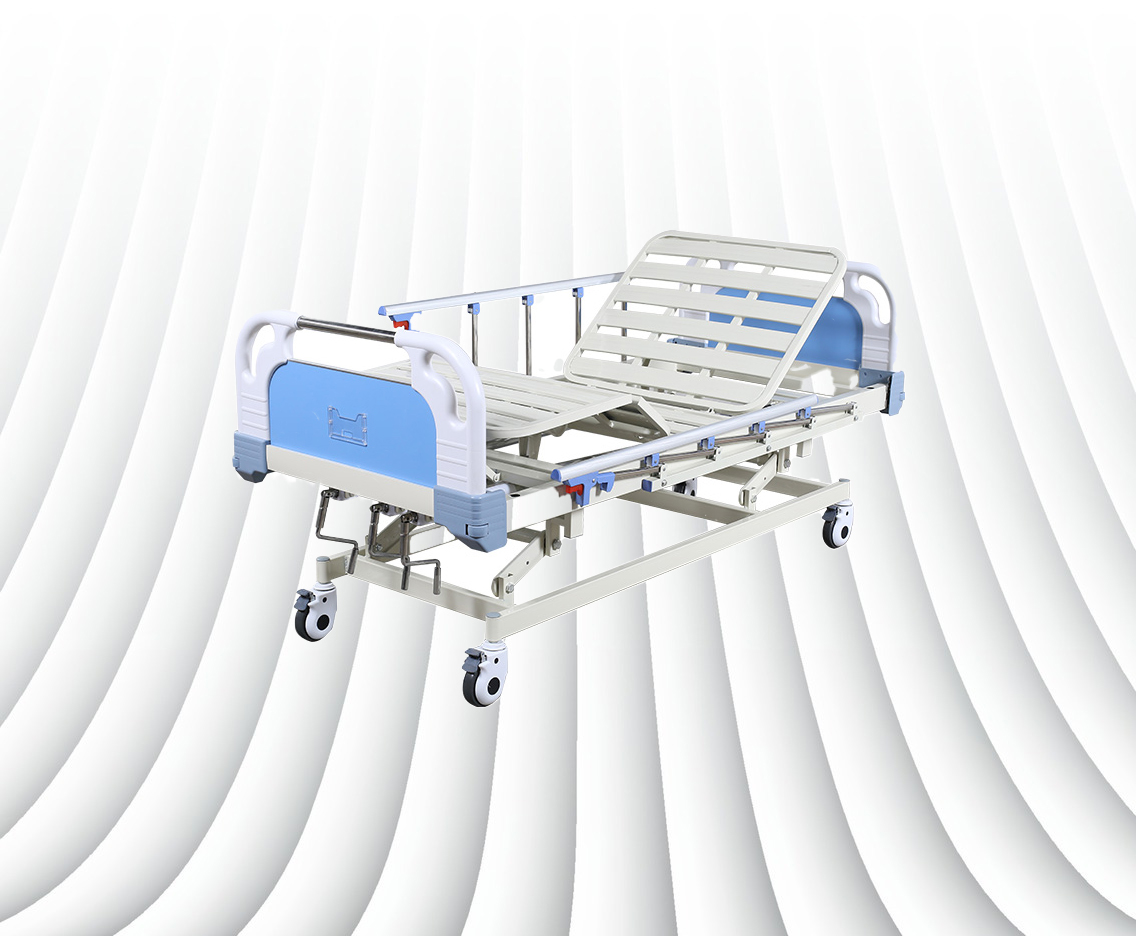

A 3 crank hospital bed (aka hand crank 3 function hospital bed) lets you adjust backrest, legrest, and overall bed height with separate cranks. No dependency on control boxes. Less noise. Lower maintenance. For general wards, long-stay rooms, and home care upgrades, this format just works. If you need plug-free reliability or you’re building a mixed-fleet with simple training, this is your guy.

Want the full lineup first? Here’s the category page:

➡️ 3 Crank Hospital Bed

Not all suppliers customize the same way. In practice, you’ll meet three supplier archetypes. Each one can be the “right” choice depending on your volume, lead time, and brand plan.

Best for: brand owners, distributors doing repeat orders, hospitals standardizing across sites.

Customization: logo & packaging, bed board style (single/double/whole), head/foot boards (ABS choices), side rails, casters with central lock, accessories bundles (IV pole, overbed table, mattress), color chips, labeling, barcode.

Why choose: stable BOM, documentation on file, consistent weld & coating, easier QA audit.

Where to start (click SKUs):

Best for: project orders with odd room sizes, mixed rails, or niche accessories; faster small tweaks.

Customization: drawing-based tweaks (hole patterns, drip stand sockets, accessory mounts), rail swaps, caster brand swaps, special board combinations.

Why choose: nimble engineering changes; you can lock a weird spec without spinning a whole new mold.

Heads-up: document every tweak (photos + drawings), or you’ll get spec drift later.

Best for: one-off bulk, quick bundles for home care, NGOs, or expanding a HOSPITAL BED SOLUTIONS program fast.

Customization: mostly cosmetic (logo, packaging), plus flexible accessory kits.

Why choose: speed to quote, broad portfolio.

Heads-up: request QC photos per batch; confirm rail/board thickness and caster locks in writing.

| Supplier type | Customization scope | QA & documentation | Lead-time flexibility | Who benefits most |

|---|---|---|---|---|

| OEM/ODM manufacturer | Deep: logo, packaging, boards, rails, casters, color, accessory bundles | Strong: BOM freeze, process sheets, batch records | Medium (planned slots) | Distributors & importers, hospital groups |

| Regional fabricator | Medium-to-deep: drawing-based tweaks, rail/caster swaps | Medium: photo/fixture checks; requires clear drawings | High on small changes | Project buyers, retrofit programs |

| Trading/marketplace | Light-to-medium: cosmetic + bundles | Varies; request per-lot photos | High for standard builds | Fast-moving bulk, home care wholesalers |

Pro tip: regardless of supplier type, insist on a one-page spec lock: rails model, board type, caster diameter & brake mode, angles & height travel, labeling.

If you’re focused on hand crank (no power dependency), these SKUs give you clean paths to brandable builds:

Wanna switch to electric later? Keep the frame dimensions consistent now so you can fleet-upgrade down the road with matching mattresses and rails. That’s how you avoid a warehouse full of “almost fits, but not quite”.

Sometimes you need the same three functions, but powered. Reasons: unified staff training, centralized controls, or your facility standard is already electric. In that case, stay in the 3 function family so accessories remain compatible:

Why keep electric + manual under the same HOSPITAL BED SOLUTIONS umbrella? One training deck, one spare parts bin, smoother PM schedules. Less chaos, honestly.

This is the boring bit that saves you later. Yes, it’s worth it.

| Scenario / use case | Recommended SKU(s) | Why this pick |

|---|---|---|

| General ward refresh with fast rollout | CZ3-B | Single board = simple build, easy cleaning; quick onboarding |

| Mixed fleet in multi-site hospital | CZ3-A, CZ3-C | ABS boards and rails with stable supply; consistent look across sites |

| Tight rooms / narrow doors | CZ3-B1 | Compact deck options; easier maneuvering |

| Project with higher maintenance access | CZ3-B (Double Board) | Two-piece board eases under-deck checks |

| Unified electric + manual policy | CZE3-1, CZE3-2 | Keep 3 functions but add power; accessories still align |

| Bulk tender with logo/packaging | CZ3-A + custom carton | Smooth OEM/ODM: branding and labeling baked-in |

We design and build Hospital Beds, Home Care Bed, Hospital Bedside Cabinet, Hospital Overbed Table, Ward Screen, and Hospital Bed Furniture for distributors, importers, hospitals, long-term care, and home users. Our OEM/ODM team doesn’t just slap a logo—we help you freeze the BOM, align accessories, and standardize a HOSPITAL BED SOLUTIONS kit that scales. You get repeatable quality and, yeah, less firefighting.

If you only remember one thing, make it this: specs first, photos second, label proof third. Do these three, and your 3 crank program runs smooth.

That’s the playbook. Short, practical, and zero fluff. If you want, I can turn this into a landing page block with CTAs and a quick RFQ form—fast edits, no drama.