Hospital bed mattresses sit at the center of everyday care. They touch every shift, every move, every wipe-down. Sounds simple, right? Not quite. When the surface fails—even tiny tears or foam fatigue—you get hygiene risk, poor comfort, and more staff workload. This piece keeps it real: quick evidence, plain-English takeaways, field-tested checklists, and where OEM/ODM choices actually save headaches.

| Argument (keyworded) | Evidence summary | Impact on patient care & safety | Notes for managers |

|---|---|---|---|

| Mattress cover damage prevalence | Multi-site audits reported a high proportion of covers with tears, abrasion, staining; many needed cover-only replacement, some needed full unit swap. | Higher cross-contamination risk; more clean-back time for ES teams; trust in hygiene slips. | Track defects by batch/SKU; keep swap stock on hand. |

| Not only old units fail | Early-life failures observed on units <4 years in use. | Age-based replacement cycles miss risk windows. | Use condition-based triggers inside your PM cycle. |

| Inspection beyond the surface | Inside seams and zipper tracks hide micro-tears; standard quick wipes don’t reveal them. | Missed defects = repeat cleaning loops and risk. | Unzip, torch-check seams, log findings. |

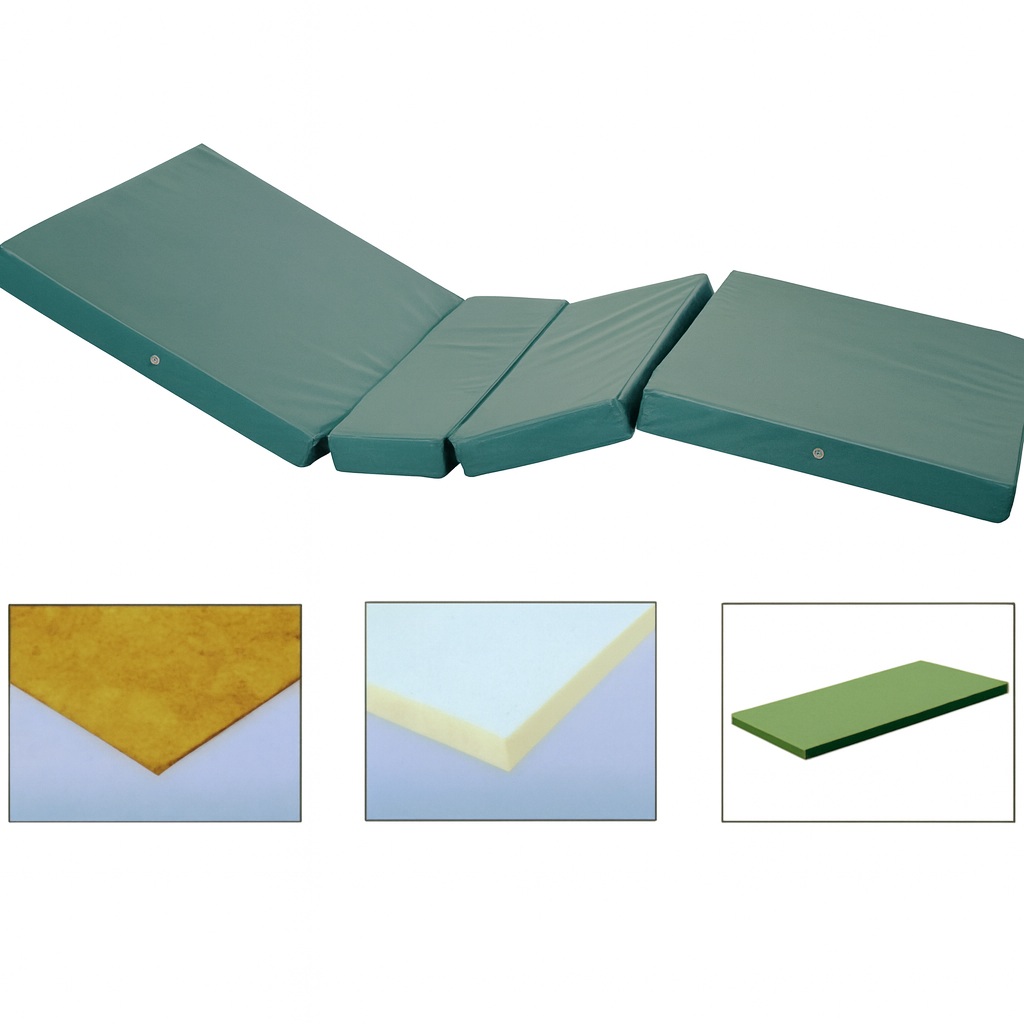

| Support layer degradation | Foam compression / gel slump reduces support profile. | More repositioning calls; increased discomfort; potential skin breakdown risk. | Add “hand-press” depth check and flatness test to PM forms. |

When mattress covers split, fluids can seep inside and later wick back out—big hygiene red flag. Even tiny pinholes matter. You don’t wanna find that out in the middle of a bed turnover. Build a routine:

Quick risk cues (keywords: mattress cover damage, hygiene risk):

| Task (keyworded) | Who | Frequency | How to verify | Pass/Fail hint |

|---|---|---|---|---|

| Unzip & seam check | ES / Nursing | At terminal clean | Flashlight on inner seams & corners | Any pinhole/tear = replace cover |

| Zipper integrity test | ES / Biomed | Monthly | Full run open/close, feel for snags | Snag or gap = swap |

| Hand-press support test | Nursing / Biomed | Monthly or on complaint | Press palm mid-zone; compare rebound left/right | Deep dip or slow rebound = flag |

| Label & IFU check | Biomed | Quarterly | Confirm IFU, lot, install date in log | Missing label = quarantine |

| Surface wipe audit | ES Lead | Weekly random | ATP or visual wipe test (per SOP) | Fail = retrain + re-audit |

Add it to your PM cycle, keep the log. Boring? Maybe. Effective? Yup.

Hospital bed mattresses with uneven support create hot spots and fidgeting. Patients shift more, staff answer more calls, everyone gets cranky. You can’t promise spa-level sleep, but you can avoid the “it hurts here when I lie flat” loop. Quick wins:

Follow the IFU (instructions for use)—full stop. But also make it practical:

This ain’t complicated, but it’s easy to skip when the floor is busy.

Regional hospital ICU swap-out

One 300-bed facility in Southeast Asia ran a spot audit after staff kept reporting “mystery stains” during terminal cleans. They found nearly half of their ICU hospital bed mattresses had tiny seam tears. Management switched to OEM/ODM covers with sealed zippers and set a quarterly unzip check.

Result: Turnover times dropped, the nurse stopped fielding daily complaints, and procurement logged fewer emergency mattress buys.

Long-term care center pressure issue

A senior care home noticed rising calls about discomfort and more late-night repositioning. The audit showed foam slump on many of the long-stay ward mattresses. After upgrading to multi-zone support models (sourced from HOSPITAL BED SOLUTIONS), night shift staff reported fewer repositioning requests, and residents said it “felt more even.”

Outcome: No fancy data—just fewer complaints and calmer nights.

Keywords: OEM/ODM, hospital bed mattress, procurement, HOSPITAL BED SOLUTIONS.

If you’re building a category plan, plug these into your RFP and vendor scorecard under “HOSPITAL BED SOLUTIONS.”

Mattress performance lives or dies with the bed itself. Tilt range, deck gaps, and rail design change the real feel. When you plan a refresh, think in sets:

Explore: Hospital Bed Mattress category pages on our site for specs and options made for real-world turnover.

We do OEM/ODM, bulk orders, and distributor programs—built for medical equipment distributors and importers, hospital procurement teams, long-term care facilities, plus home-care buyers.

Hospital bed mattresses aren’t a “set and forget.” Covers tear, cores slump, and visual checks miss stuff. Shift to condition-based PM, unzip and inspect, stock cover swaps, and buy with IFU compliance + traceability in mind. If you want an easy on-ramp, our HOSPITAL BED SOLUTIONS lineup aligns with this playbook and plugs into your Hospital Bed Furniture sets without fuss.